Vivid dyes using Mt. Fuji spring water

The dyeing process using Mt. Fuji spring water produces fabrics of vivid hues only found in the Yamanashi region. The water itself undergoes a long process of natural filtration in which rain water and melted snow runoff from Mt. Fuji seeps into the earth and undergoes a long process of natural filtration. The water itself is thus soft and lacks the chemicals that would otherwise interfere with the dyes added to the water, resulting in the most vivid dyes.

“Sakizome” thread dyeing method

There are three methods of dyeing textiles: dyeing an already finished product, dyeing material, and dyeing thread prior to weaving. Yamanashi textiles are produced by “sakizome,” the method of dyeing thread prior to weaving. It is the most complex and time consuming of the three methods, and results in high-grade color and texture.

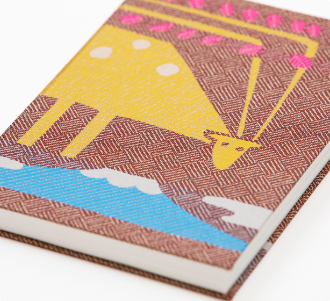

Different threads are used vertically and horizontally

Different threads are used vertically and horizontally Colors change depending on the angle

Colors change depending on the angle

Smooth, elegant textures achieved by delicate, fine threads

The use of fine thread results in the production light, thin fabric. However the finer thread, the more difficult it is to handle during the production process. Since the era when fabrics were produced using hand looms, Yamanashi textile manufacturing was famous for producing high-grade materials with “kenshi” silk fibers, the finest of all natural fibers. This technique has been handed down and the region has come to be known for the expert handling of this tricky fine thread in its production of high quality textiles.

Polyester thread

Polyester thread Intricate luster of fine silk

Intricate luster of fine silk

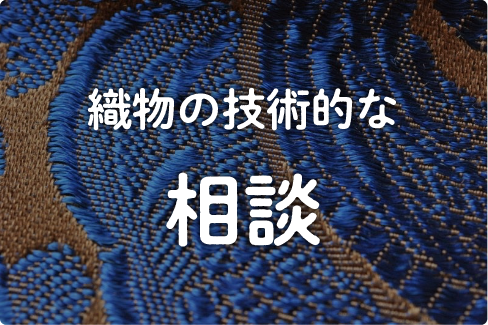

Meticulously woven patterns create high density textiles

Striking colors and patterns are created by interweaving high volumes of fine threads. While the use of even a couple thousand threads is considered high in volume, Yamanashi textiles are produced by interweaving over 10,000, using the technique and know-how of generations past. The illusion of depth and level of quality that result are defining characteristics of the textiles produced in the region.

An illusion of depth created by interweaving vertical and horizontal threads

An illusion of depth created by interweaving vertical and horizontal threads Smooth curves can be achieved by using fine thread

Smooth curves can be achieved by using fine thread

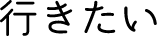

Quality over quantity in production

Yamanashi textiles are produced predominantly in small, family-run factories that make use of the small scale of production to pour attention into detail and quality. We live in an era of reducing wastefulness and trying to make quality items last. Does it not seem that the manufacturing style of this region meets the demand? Yamanashi textile manufacturing honors the idea of valuing quality over quantity by remaining committed to small scale production.

For textile artisans, weaving a normal part of life

For textile artisans, weaving a normal part of life Meticulous and precise craftsmanship in production

Meticulous and precise craftsmanship in production

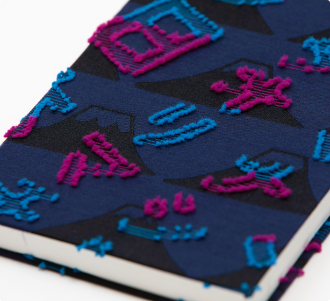

Versatility

Yamanashi textile manufacturers are known for their expertise in the challenging production of high quality, high density textiles. They are therefore well equipped to meet the demand for a wide variety of needs. Currently there are specialists in the production of neckties, interior goods, lining, umbrella cloth, shawls and dress materials.